Radiography Testing for Aluminum Castings

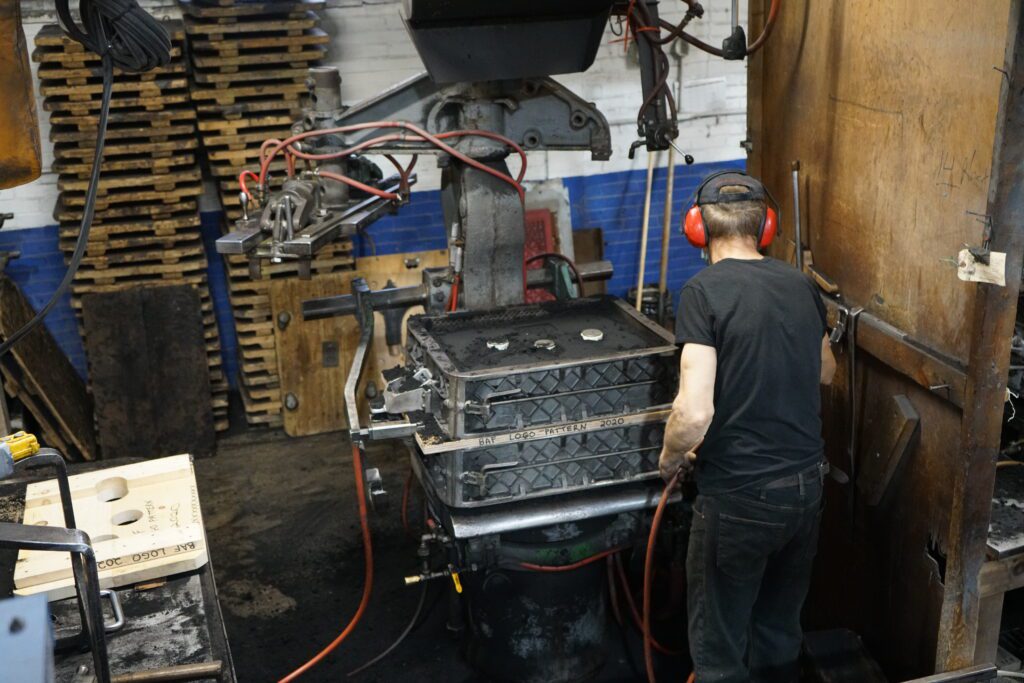

Your reputation depends on delivering defect-free, structurally sound castings. At Boose Aluminum Foundry, we offer radiography testing to ensure internal soundness and reliability, because unseen flaws can lead to costly failures down the line. All radiographic evaluations are tailored to your specifications and integrated into our production plan.

What Is Radiography Testing?

Radiography testing (commonly called X-ray testing) is a nondestructive testing method that uses X-rays to examine the internal structure of our parts. It enables our technicians to detect internal anomalies, such as shrinkage, voids, inclusions, or porosity, without damaging or altering the part.

We utilize radiographic testing as a quality assurance checkpoint to verify the integrity of critical aluminum castings before final inspection and delivery. This process ensures confidence in performance, safety, and compliance.

Why Radiographic Testing Matters

For parts that need to perform under stress, reliability starts inside the casting. Here’s why our customers depend on this service:

- Internal Defect Detection – Radiography pinpoints internal casting defects that compromise strength.

- Reduced Failure Risk – Early identification of discontinuities prevents downstream issues, such as cracking, leaks, or in-field part failures.

- Cost-Effective Quality Control – Avoid machining defective castings or scrapping finished parts. Radiography ensures only good castings advance.

- Traceable Inspection Records – Radiographs provide permanent documentation of part quality.

Who Uses Radiography Testing?

Boose Aluminum Foundry supports industrial companies that need high-integrity aluminum castings. Our radiographic testing services are typically used by:

- Defense contractors

- Heavy machinery manufacturers

- Automotive and motorsports performance teams

- Pumps, valves, and fluid handling manufacturers

- Utilities and infrastructure contractors

These customers often operate in high-pressure environments where failure is not an option. Radiographic inspection ensures their components meet their requirements and specifications.

Ideal Use Cases for Radiographic Inspection

Not every part requires radiographic evaluation. However, this method is ideal for:

- Critical components with load-bearing or sealing requirements

- Parts with complex internal geometry or thick sections

- Castings with a history of porosity or shrink defects

- Applications involving pressure, motion, or vibration

- Parts undergoing military or OEM contract inspection requirements

We do not offer this as a stand-alone service—it is part of our comprehensive casting process. This service is only available for aluminum castings manufactured at our facility.

Why Choose Boose Aluminum Foundry?

Industrial buyers trust Boose Aluminum Foundry because we do more than pour metal. We deliver the results you need.

Responsive Communication

You get clear updates, fast quotes, and dedicated support from project kickoff to final delivery of all your aluminum projects.

Competitive Pricing

With in-house testing and streamlined operations, you’ll get efficient aluminum casting solutions.

Production Efficiency

We move from design to delivery with speed and precision, thanks to our agile processes and skilled team.

Quality Control

Every part is evaluated to ensure it meets your standards.

Design Support

We provide rapid prototyping, 3D scanning, and design for manufacturability (DFM) to reduce defects before they start.

Sustainability Focus

We reclaim molding sand, and design our processes to conserve energy and reduce landfill waste.

FAQs About Metal Radiography Testing

Have questions about radiography testing and how it fits into your casting project? Here are some quick answers to help you understand what to expect and how Boose Aluminum Foundry supports your quality requirements.

What is the difference between radiographic testing and ultrasonic testing?

Radiographic testing utilizes X-rays to capture a visual image of internal structures, making it ideal for detecting volumetric defects. Ultrasonic testing utilizes sound waves and is more effective for detecting cracks in solid sections; however, it is less effective with complex castings.

Is radiographic testing safe?

Yes. Our team adheres to strict safety protocols and utilizes shielded facilities to safeguard operators and ensure compliance with radiation safety regulations.

Do I need to request this service separately?

Yes. The requirement or specification must be identified on the Request for Quote and the purchase order.

How do I receive inspection results?

You’ll receive radiographic images, written reports, and evaluation summaries as part of our documented quality assurance process.

Get a Quote or Start Your Project

When quality assurance matters, metal X-ray testing is a smart investment. If you’re sourcing aluminum castings and require internal verification, Boose Aluminum Foundry can assist you.

Let’s talk. Contact us today and discover how we can help align with your production goals.