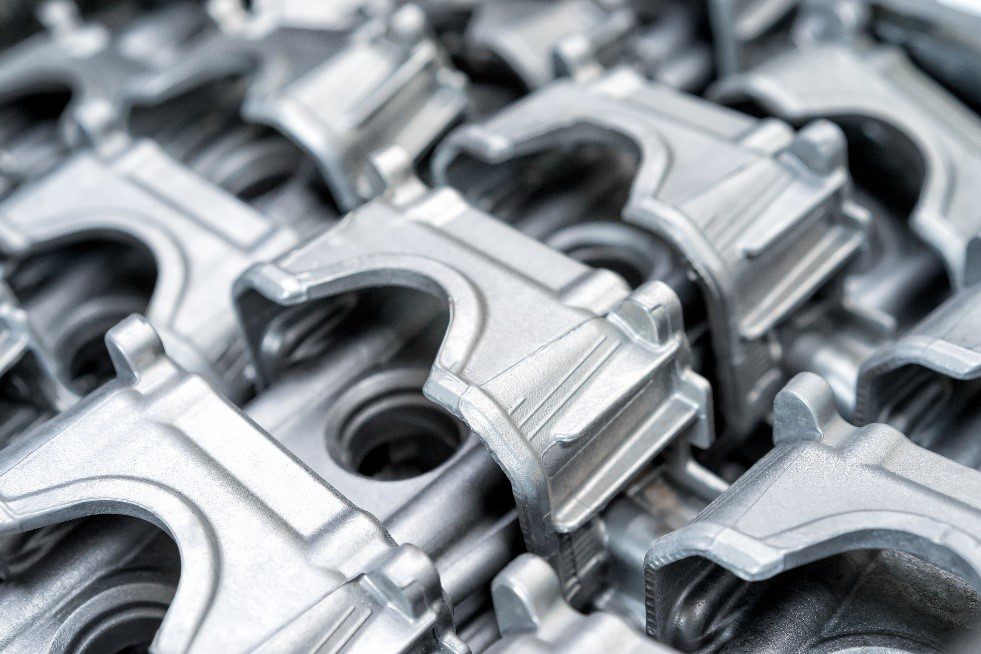

Brinell Hardness Testing at Boose Aluminum Foundry

Are you looking to work with a foundry that understands the importance of producing high-quality castings? When you choose Boose, you can feel confident that we will ensure your aluminum castings are sound, well-made, and, where applicable, pass the Brinell Hardness Test.

What Is the Brinell Hardness Test?

The Brinell Hardness Test measures a material’s resistance to indentation by applying a defined load using a hardened steel or tungsten carbide ball. The diameter of the resulting impression is measured and used to calculate the Brinell Hardness Number (BHN). This number clearly indicates the material’s overall strength and uniformity.

The test is governed by ASTM E10 and ISO 6506 standards, ensuring repeatable and reliable measurements across industries and applications.

What Are the Benefits of Brinell Testing?

- Reliable for coarse-grained structures – unlike other methods, Brinell testing effectively handles rough casting surfaces and heterogeneous materials.

- Excellent for large components – ideal for parts that are too thick for superficial surface methods.

- Standardized and widely accepted – recognized in industries worldwide as a dependable measure of metal hardness.

- Visual traceability – each test leaves a clearly visible mark, providing on-part confirmation and ease of re-evaluation if needed.

Ideal for Aluminum Castings

Brinell testing is particularly effective for aluminum castings, which require precise hardness control during and after manufacturing. At Boose Aluminum Foundry, we carefully calibrate our Brinell equipment to apply lower test loads appropriate for softer non-ferrous alloys. This ensures we achieve reliable results without compromising the integrity of the casting. The BHN value helps detect inconsistencies from alloying elements, heat treatment, or casting porosity—providing our team and clients with critical insights into casting performance.

How Brinell Testing Compares to Other Methods

While Brinell testing is just one of several hardness testing techniques, it stands out for specific use cases:

- Versus Rockwell: Rockwell testing uses smaller loads and penetrators and is better for thinner or machined parts. It’s not ideal for raw castings or coarse surfaces.

- Versus Vickers: Vickers testing provides very precise results and is often used in lab settings for microstructures. However, it requires a polished surface, making it less practical for production-line testing of industrial castings.

- Versus Rebound (Leeb): Portable rebound testers are convenient, but Brinell testing is preferred when documentation and standards compliance are needed.

Brinell is typically the most practical option for heavy, rough-surfaced components that don’t require surface finishing prior to testing—exactly the kind of work we specialize in at BAF.

Industries That Rely on Brinell Testing

Our integrated Brinell testing is used across a variety of high-demand sectors:

Defense and Military

Strength certification for aluminum armor components and enclosures.

Power Generation

Hardness checks on generator and turbine housing castings.

Oil and Gas

Quality control on structural and wear-resistant parts used in upstream and downstream operations.

Agriculture and Construction

Ensuring durability of mechanical systems under repeated load and exposure.

Transportation

Material strength verification on safety-critical infrastructure.

Use Cases for Brinell Certification

When you receive castings from Boose Aluminum Foundry, Brinell test results can be used to:

- Validate mechanical properties against industry standards.

- Satisfy third-party inspection or regulatory requirements.

- Assist in troubleshooting or failure analysis.

- Monitor alloy behavior over repeated production runs.

We offer Brinell Certification upon request, providing documentation of test results, equipment calibration, and testing conditions—all traceable to the specific batch or part number.

The Role of Brinell Results in Quality Assurance

Hardness testing is more than just a routine check—it’s a foundational part of our QA program. Brinell test results are:

- Logged and archived for every applicable casting.

- Linked to customer specifications and casting drawings.

- Reviewed during final inspection before release or shipment.

This process ensures that each part meets its expected structural and performance requirements before it ever reaches your production floor.

Frequently Asked Questions

If you are looking to work with a foundry that offers Brinell Hardness Testing for your cast components, you may have a few questions about how it works and why it’s important. Below are answers to the most common inquiries we hear from industrial buyers and engineers alike.

What is Brinell Hardness Testing used for?

Brinell testing is used to assess a metal’s resistance to deformation under load. It’s especially effective for coarse materials like castings or forgings.

Can Brinell Testing be done on aluminum?

Yes, Brinell testing is commonly used for aluminum. Special loads and balls (often 10mm with 500 kgf load) are selected to suit softer metals.

Is Brinell better than Rockwell?

Not necessarily better—just different. Brinell is more suited for rough, bulky parts, while Rockwell works well on machined or thin components.

Do I need to request Brinell testing separately?

When specifications require, it’s included as part of our casting QA process. However, certifications can be requested at the time of order.

Does Brinell testing damage the part?

This testing leaves a small indentation, typically in a non-critical location. It does not usually affect function and provides visible evidence of testing.