3D Printed Sand Molds and Rapid Prototype Casting

When speed and precision matter most, 3D printed sand molds and rapid prototype casting offer an efficient way to bring your designs to life. At Boose Aluminum Foundry (BAF), we provide these advanced solutions exclusively for customers producing their castings through our foundry.

While we partner with trusted service providers for the printing of the sand mold, all casting work is performed in-house, ensuring the final product meets BAF’s exacting standards.

Whether you’re facing tight deadlines, testing new designs, or moving production stateside, BAF’s rapid prototyping services help you move from concept to casting quickly and reliably.

What Is 3D Printed Sand Molding and Rapid Prototype Casting?

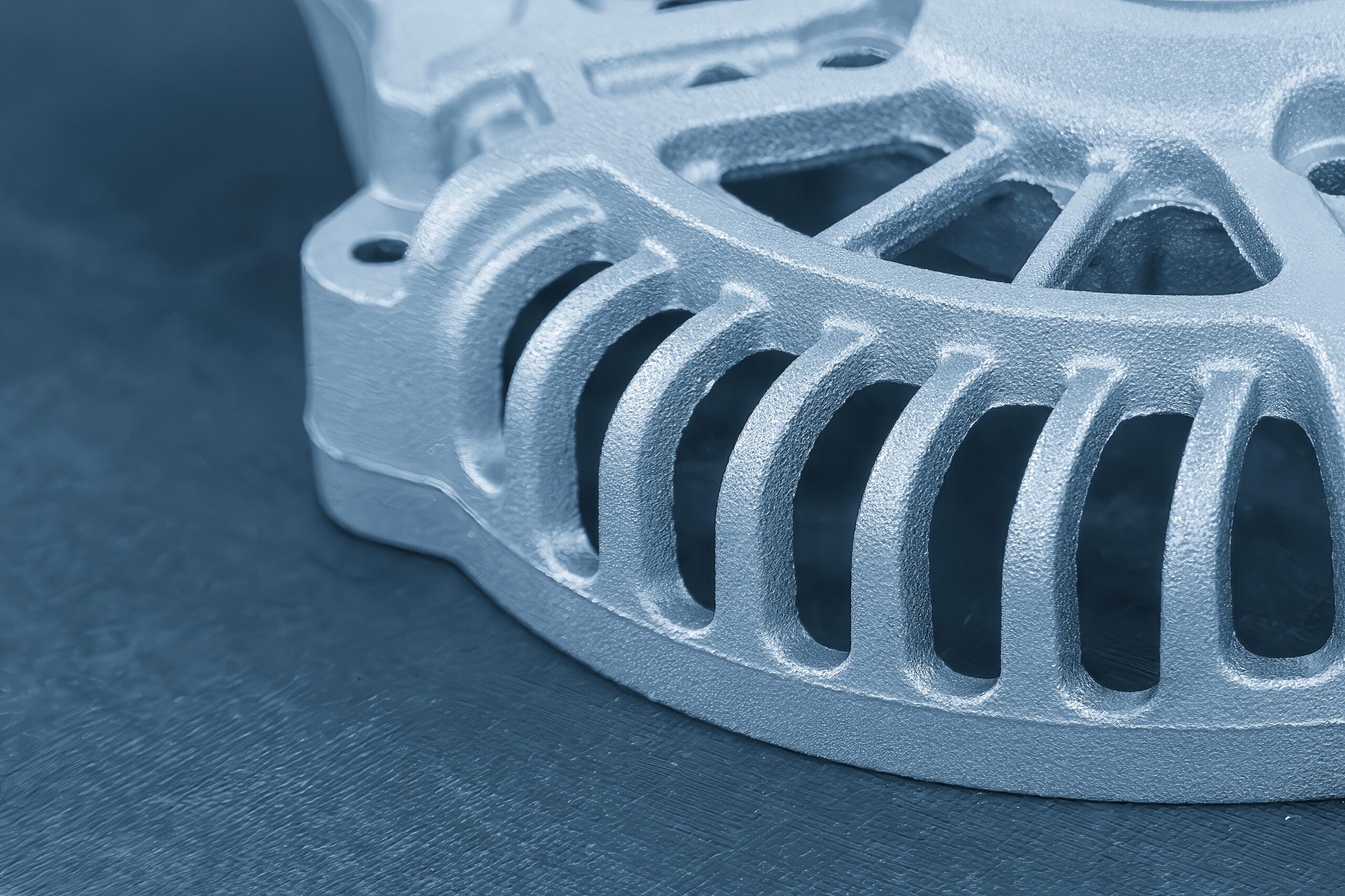

3D printed sand molds are created using additive manufacturing technology to build precise 3D printed sand cores and molds layer by layer from digital CAD models. Unlike traditional mold-making, which can require time-consuming tooling, 3D printing directly produces complex geometries with remarkable accuracy. While BAF does not print molds in-house, we work closely with specialized service providers to produce sand molds that meet our stringent specifications.

Rapid prototype casting is the process of producing metal castings from these 3D printed sand molds. This method enables manufacturers to evaluate design performance, fit, and function before committing to full-scale production. For our customers, this means faster iterations, lower upfront tooling costs, and the ability to test designs with production-quality castings—all with the trusted expertise of Boose Aluminum Foundry.

The Benefits of 3D Printed Sand Molds and Rapid Prototype Casting

Choosing 3D printed sand molds and rapid prototype casting offers several advantages:

- Speed to Market: Eliminate long lead times associated with traditional tooling. Move from design to casting in weeks, not months.

- Complex Geometries: Produce intricate internal features and optimized designs that would be impossible with conventional methods.

- Cost-Effective Prototyping: Avoid permanent tooling investments by reducing short-run production and product development costs.

- Design Flexibility: Quickly implement design changes and reprint molds with minimal disruption.

- Onshore Production Support: With shifting global supply chains and increasing tariffs, rapid prototyping supports reshoring initiatives and ensures domestic manufacturing reliability.

Industries That Benefit from 3D Printed Sand Molds and Rapid Prototype Casting

At Boose Aluminum Foundry, we serve a wide range of industries where precision, durability, and speed are critical. For these industries, the ability to test new components, accelerate development cycles, and respond to market demands with agility is essential.

Aerospace

Defense

Automotive

Heavy Equipment

Industrial Machinery

Energy

Common Use Cases

Our 3D printed sand molds and rapid prototype casting services are ideal for:

- Design Validation: Create functional prototypes for testing and approval before full production.

- Legacy Part Replacements: Manufacture hard-to-source components without existing tooling.

- Custom, Low-Volume Parts: Produce unique parts where conventional tooling would be cost-prohibitive.

- Pre-Production Samples: Provide early samples for customer evaluation.

When you plan on casting your product with us, your mold will be printed to exact specifications and shipped to BAF for pouring and finishing, ensuring a seamless process from print to finished casting.

Why Choose Boose Aluminum Foundry for 3D Printed Sand Molds

and Rapid Prototype Casting?

While dedicated external providers produce sand printed mold, every casting made from these molds is poured and processed at Boose Aluminum Foundry, giving you the confidence of working with a foundry that prioritizes quality, precision, and customer service.

Here’s why manufacturers trust BAF:

- Trusted Partnerships: We collaborate with industry-leading sand printing providers to ensure superior mold quality.

- In-House Casting Expertise: All metal pouring, finishing, and inspection are performed by our experienced team in our Pennsylvania facility.

- Reliable Domestic Production: As reshoring trends continue, we offer a dependable alternative to offshore manufacturing.

- Decades of Foundry Excellence: With a long-standing reputation in the aluminum casting industry, BAF brings unmatched knowledge and service to every project.

- Customer-First Approach: Our 3D printed sand mold and rapid prototype casting services are available exclusively for BAF customers, ensuring every project receives our full attention and expertise.

Partner with Boose Aluminum Foundry for Your Next Project

If you’re exploring the benefits of 3D printed sand molds and rapid prototype casting, Boose Aluminum Foundry is ready to help. We bring your designs to life with precision, speed, and the quality assurance you expect from a trusted foundry partner.

Contact us today to learn how our prototype casting solutions can accelerate your next project.